A professional quality team, a stable and reliable production management system, and advanced testing equipment ensure quality service.

ELECTRONIC MANUFACTURING

MARKET SECTOR

NEWS

86-13913128991

86-13913128991 A professional quality team, a stable and reliable production management system, and advanced testing equipment ensure quality service.

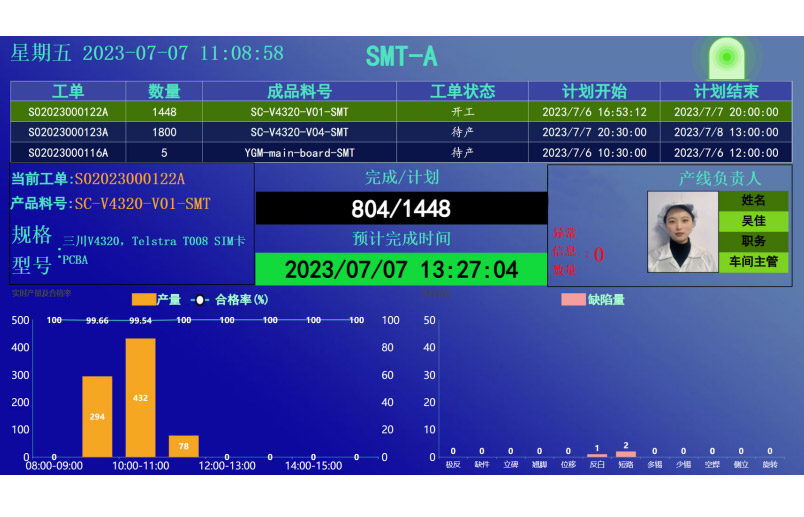

The commercial MES management system is more stable and reliable, and can interface with customer testing programs to automatically upload test results. The main functions include: automatic processing and inspection of engineering documents, work order management, process error prevention and error prevention, intelligent material rack storage, product and material traceability, quality monitoring dashboard, and other functions, achieving full process tracking and monitoring management from incoming materials to delivery.

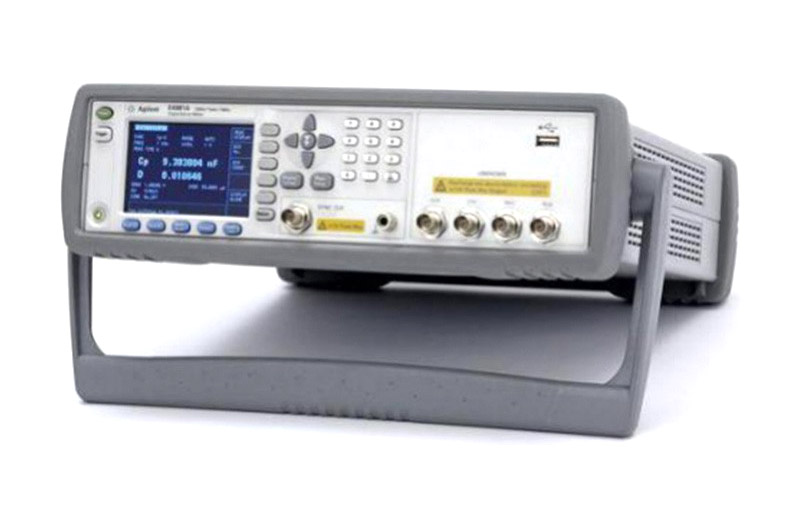

Whether it is self purchased or customer supplied materials, we will strictly follow the AQL standard requirements for quality confirmation and verification, and have precision LCR (measurement range: 20Hz to 20MHz) and other equipment guarantees.

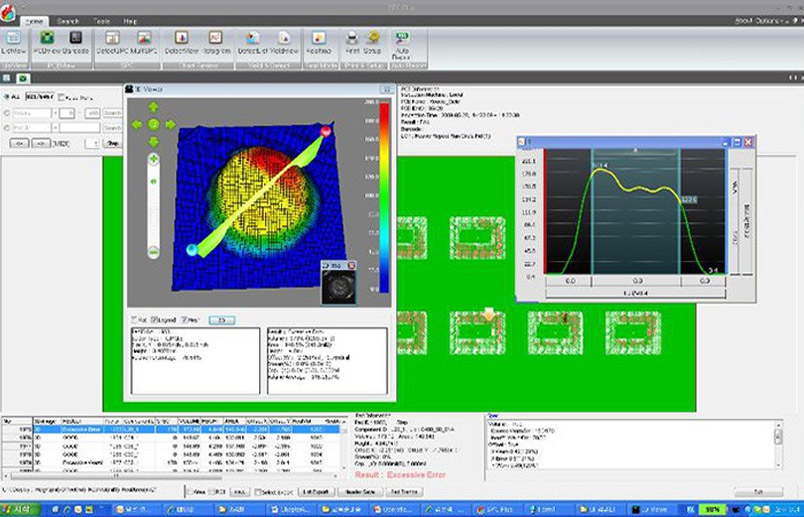

Although using MPM and Panasonic's high-precision fully automatic printing machine, we use Koh Young 3D SPI for 100% solder paste printing inspection on each product to ensure the quality of the solder paste printing process.

The MES system includes loading error prevention and refueling reminder functions to ensure efficient and error free operations. Using high-precision AOI visual processing technology to automatically detect various visible installation errors and welding defects; Use an X-ray detector to perform non-destructive testing on the tin climbing height of invisible BGA bubbles and through-hole devices, ensuring product stability and reliability.

To avoid visual fatigue and quality risks caused by naked eye testing, we have introduced a DIP welding AOI testing equipment with Z-axis adjustment to ensure more stable and consistent quality.

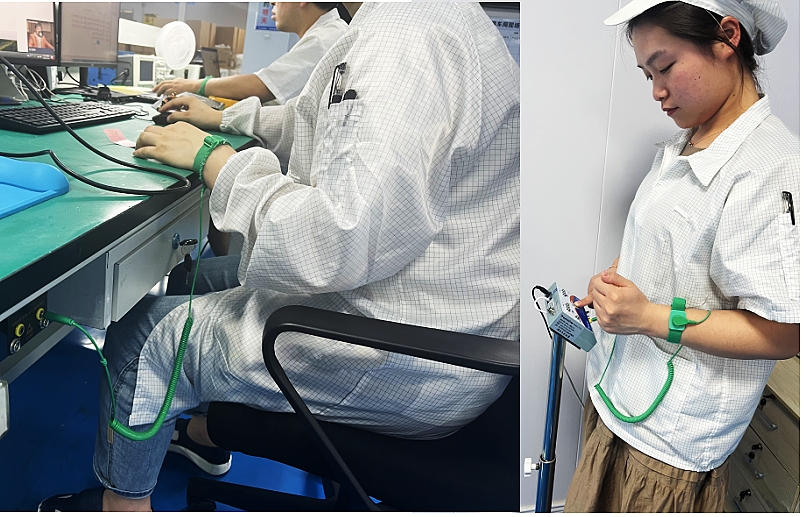

Electrostatic pile system: 4 3-meter ground piles and 3 resistance reducing blocks are connected by hot melting with 20 meter copper stranded wire and buried underground.

Secondary wiring: 10 square meters of copper wire distributed on top, welded electrostatic pile system.

Connect the static wire to the static floor, static bracelet, and static leather. Connect the grounding wire of the yellow line equipment to the equipment.

We can provide customers with a reliability testing environment, including high and low temperature tests, vibration tests, drop tests, etc.

High and low temperature test chamber:

Temperature range: -40 ℃ -150 ℃.

Humidity range: 20-98% R.H.

Accuracy range: temperature ± 0.1 ℃, humidity ± 1% R.H.