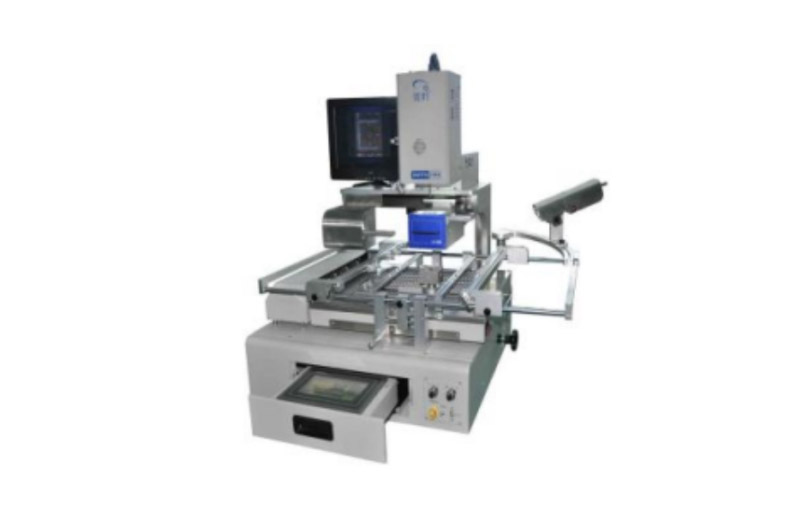

The company has 3 plug-in lines, each equipped with DIP furnace front AOI, lead-free wave soldering, and furnace rear solder joint detection AOI.

DIP is an electronic component packaging technology commonly used for components such as integrated circuits, crystal oscillators, inductors, and capacitors mounted on PCBs.

Idealink has high peak and large-sized peak welding, and dual AOI before and after the furnace provides assurance for DIP welding quality.

ELECTRONIC MANUFACTURING

MARKET SECTOR

NEWS

86-13913128991

86-13913128991

Haoxw@idea-link.com.cn

Haoxw@idea-link.com.cn