ELECTRONIC MANUFACTURING

MARKET SECTOR

NEWS

86-13913128991

86-13913128991  86-13913128991

86-13913128991

In 2025, Idealink's SMT surface mount welding process officially introduced SMT welding processes for solder and plastic parts, achieving a major breakthrough in its own welding technology and receiving good market response.

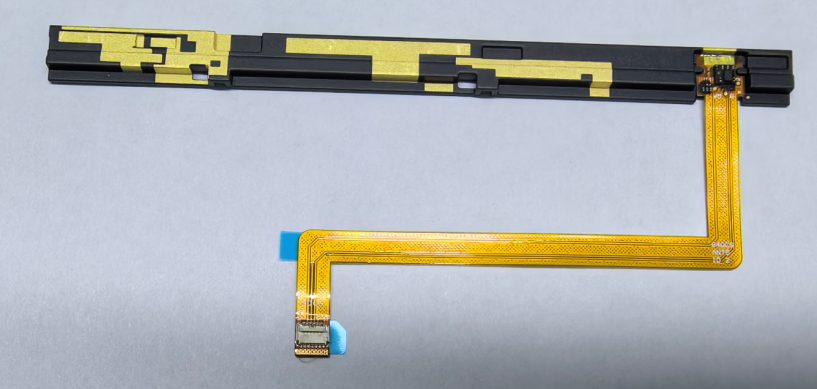

Soldering technology refers to the precise addition of solder at designated locations on a circuit board, facilitating the soldering of components. This technology significantly improves welding efficiency and consistency, reducing errors and quality risks caused by manual labor. The soldering technology uses a computer to precisely control the robotic arm, in conjunction with the soldering nozzle, to complete the soldering operation by programming the soldering path and parameters. Tin deposition technology has high precision, accuracy, flexibility, and efficiency, making it suitable for batch SMT motherboard soldering processes of micro and small electronic components, and also more suitable for the current intelligent and multifunctional application prospects. The successful introduction of this technology by Idealink indicates a substantial improvement in its own technological strength.

Idealink uses spot soldering technology and SMT welding process for plastic parts, which can quickly undertake and independently complete complex and precise welding requirements such as LDS antennas, as well as non planar welding requirements. At the same time, its carrier and furnace temperature local precise temperature control technology can fully ensure the one-time molding and high yield rate of this welding technology. Therefore, it has a good market application prospect and excellent and stable overall process competitiveness.

86-13913128991

86-13913128991  Haoxw@idea-link.com.cn

Haoxw@idea-link.com.cn